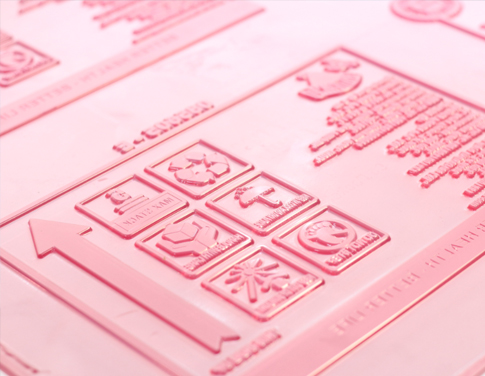

Trusted Experts in Flexographic Prepress & Printing Technologies

Halftone Flexotech Private Limited was founded with the objective of elevating print quality and operational efficiency within the packaging and printing industry. From flexo prepress and HD flexo plates to advanced die-making and embossing solutions, we provide end-to-end support that helps our customers stay competitive in a rapidly evolving market.

Our facilities are equipped with state-of-the-art infrastructure and globally sourced high-end machinery, enabling us to meet the most demanding technical requirements. By continuously investing in new technologies and process optimization, we ensure consistent quality, faster delivery, and scalable production.

- Professional Team

- Consistent Quality

- Cost-Effective Solutions

- Custom-Built Solutions

Our Vision

To be a globally recognized partner for innovative, precise, and sustainable flexographic and printing solutions.

Our Mission

- Deliver superior quality products with uncompromising accuracy

- Leverage advanced technology to improve efficiency and reduce waste

- Offer customized, customer-centric solutions

- Build long-term partnerships based on trust and performance

Every project – whether a prototype or a high-volume production run—is handled with meticulous attention to detail and strict quality control standards.

Your Partner in Prepress Solutions

Professional Team

Our experienced professionals bring deep technical knowledge and hands-on expertise to every project, ensuring accurate execution and reliable output.

Expertise

Decades of industry experience enable us to deliver precision-driven prepress and tooling solutions tailored to diverse packaging requirements.

Competitive Prices

We offer cost-effective solutions without compromising on quality, helping customers maintain efficiency and profitability.

Quality Service

Strict quality control, consistent performance, and responsive customer support ensure dependable service across every job.

Cost Effective

Optimized workflows and advanced technology help reduce production waste, press downtime, and overall operational costs.

Customization

We provide job-specific, customized solutions designed to match exact press conditions and production needs.