Flat Bed Laser Dies with Aluminium Base Blocks

Service Overview

Flat Bed Laser Dies with Aluminium Base Blocks

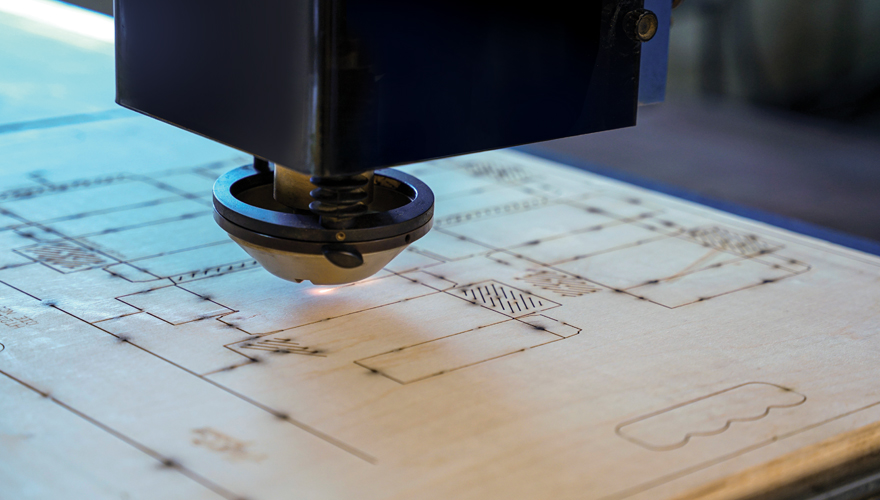

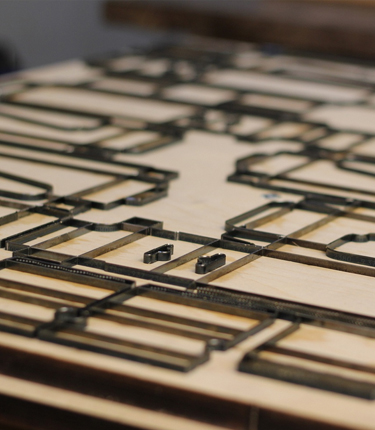

Halftone Flexotech manufactures high-precision flat bed laser dies mounted on aluminium base blocks, engineered for accurate cutting, creasing, perforating, and scoring in carton and corrugated packaging production. Designed for stability, durability, and consistent performance, our dies ensure clean cuts, precise registration, and smooth creasing for superior packaging output.

Using advanced laser cutting technology and premium-grade materials, our flat bed dies offer excellent dimensional accuracy, long service life, and reduced make-ready time on press. The aluminium base blocks provide enhanced strength, lightweight handling, and improved alignment, making them ideal for high-speed flat bed die-cutting machines.

Key Features

- Precision laser-cut tooling for exact cutting profiles

- Rigid aluminium base blocks for superior stability

- High repeat accuracy and consistent performance

- Smooth creasing and clean perforation results

- Enhanced durability for long production runs

- Optimized alignment for faster make-ready

- Lightweight construction for easy handling

- Reduced vibration during die-cutting

- Improved dimensional stability over time

- Compatible with all major flat bed die-cutting machines

Why Choose Halftone Dies

Halftone Flexotech is a trusted name in precision die manufacturing, delivering high-quality flat bed and rotary dies engineered for accuracy, durability, and consistent performance. Our dies are designed to meet the demanding requirements of modern packaging production, helping converters achieve clean cutting, precise creasing, and reliable output across long production runs.

With advanced manufacturing technology, strict quality control, and a skilled technical team, we ensure every die meets exact dimensional standards and press specifications. From cartons and corrugated boxes to specialty packaging, Halftone dies are built to enhance productivity, reduce downtime, and improve overall efficiency on press.